Method

1, Before treatment

How the surface looks before getting treated.

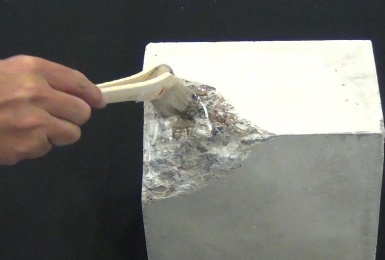

2, Applying primer

Remove dust and dregs, and apply resin primer. *In the photo, Alpron W-301 is used.

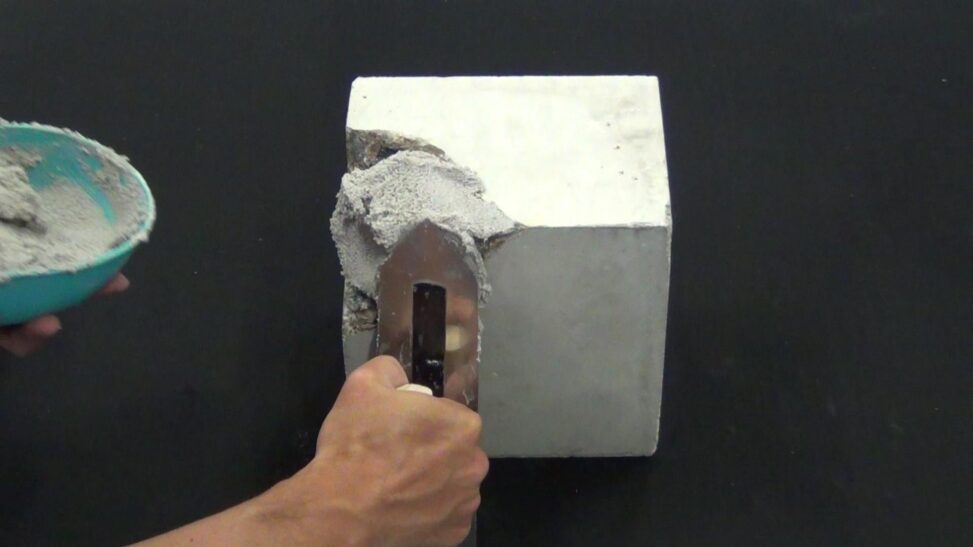

3, Filling with repair material

Knead the resin repair material to a slightly hard consistency, then apply with a trowel. *Use your fingertip to apply for the best result. *Alpron HM is used in the photo.

4, Cover the chip

Apply the material a little higher than the surface, and wait for it to harden.

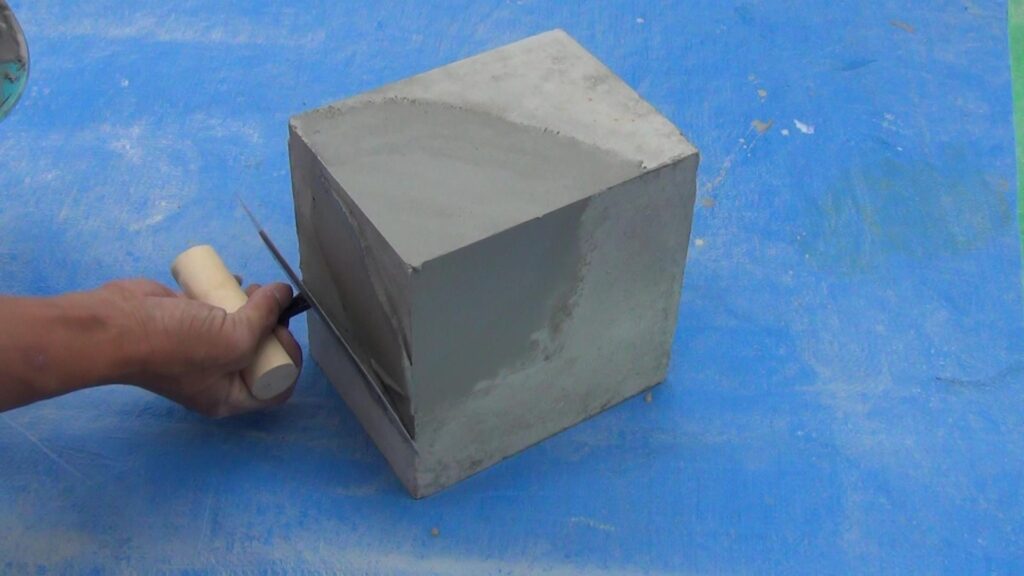

5, Shaping

Attach a Level Grinding Wheel #36 to a grinder, then start cutting little by little. Cut it down until it becomes the same level as the surface.

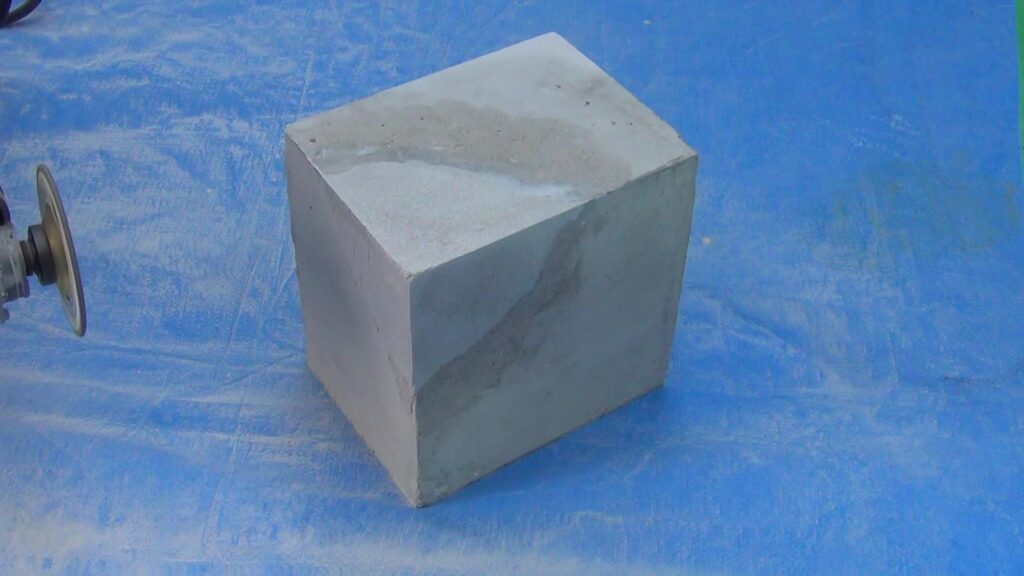

6, Primer and scraping

After cleaning the surface, apply the cement primer, then apply Repair Resin thinly. Use a scraper to scrape off any excess materials before Repair Resin dries. Any major chips or damages should disappear after this process.

7, Surface preparation

Apply C Repair Lining to blur the border and set the texture. Apply the cement primer, then apply C Repair Lining again to cover the repairing area.When dried, use #600 sandpaper to rub off any excess materials.

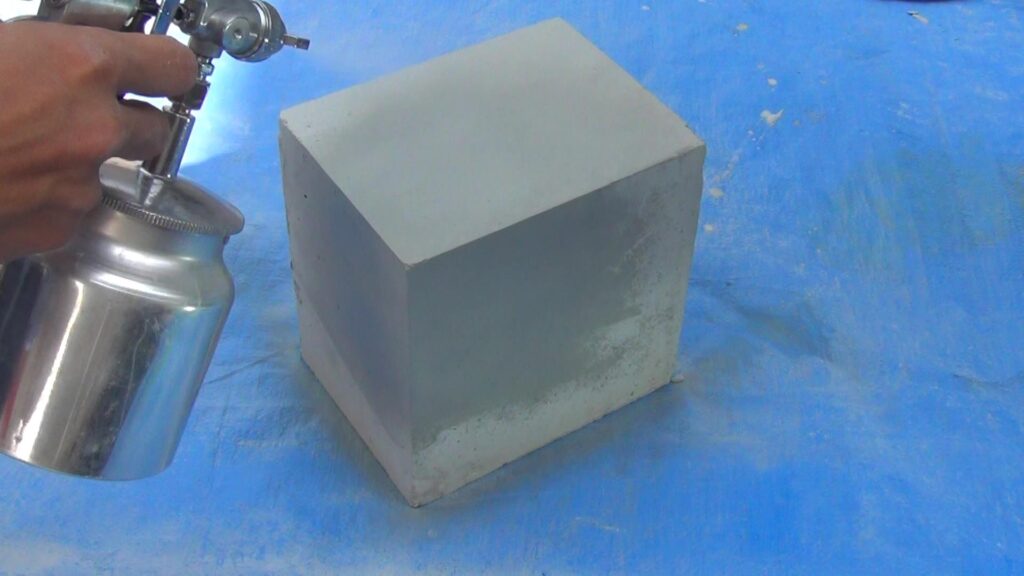

8, Spraying

Spray a small amount of C Repair Color at a time. Spray until it matches its surroundings, and the border is invisible.

9, Adding patterns

Add patterns little by little as you dry the material. Rub with #600 sandpaper from time to time. The procedure is completed when it looks natural.

Tools to prepare

- Trowel(1~2mm)

- Metal Trowel

- Bowl

- Scraper

- Waterproof sandpaper #600

- Wire brush

- Small bucket

- Brush

- Wiping cloth

- Wagner FLEXIO 570

- Air compressor

- Air hose

- Air gun

- Pattern Pad

- Gas torch

- Electric blower

- Grinder

- Level Grinding Wheel and #36/#80

Materials to prepare

- Repair Resin

- C Repair Lining

- C Repair Color

- Tone Color

- Cement primer(Royal W21 diluted about 20 times with water, etc,)

- Resin repair materials

- Resin primer

Notes

- All Repair Resin products are pre-mixed and only use water for kneading. Please note that the curing time and color may differ if any adhesives are mixed.

- Once it’s mixed with water, please use it all. Re-watering or kneading once curing has started may cause cracks and poor adhesion.

- Because it’s cement-based, it is subject to weathering and moisture absorption. Please store with care and use as soon as possible. (The 5kg inner bag is heat-sealed to improve shelf life. Please use the rubber band attached for sealing any leftover products.)

- When repairing, remove the excess unevenness of the surface beforehand with a hammer, chisel, scraper, etc., and clean it. If the mold releasing agent remains on the surface, it’ll peel off easily. Use a brush to scrub the surface and moisten it with water for the best results.

- Please be careful when handling a scraper or a metal trowel, as they may cut your hand.

- Please read the instructions and notes of C Repair Lining and C Repair Color.

- After adding the Mixing Liquid into C Repair Color, please use it all within 24 hours.

- Cover and protect the area where you don’t wish to spray paint beforehand.

- If it adheres to any unwanted area, wipe it off with a wet wiping cloth.

- Please make sure to mix C Repair Color thoroughly before use. If it’s not fully mixed, it may cause unevenness.

- Spray C Repair Color little at a time in thin layers. If you spray too thickly at once, it may drop, and the finished look will not look as good. Please repeat the process of “Spray → Dry → Spray” until the surface is fully covered.

- When adding patterns, tap lightly and inconsistently according to the surrounding patterns.

Leave a Reply